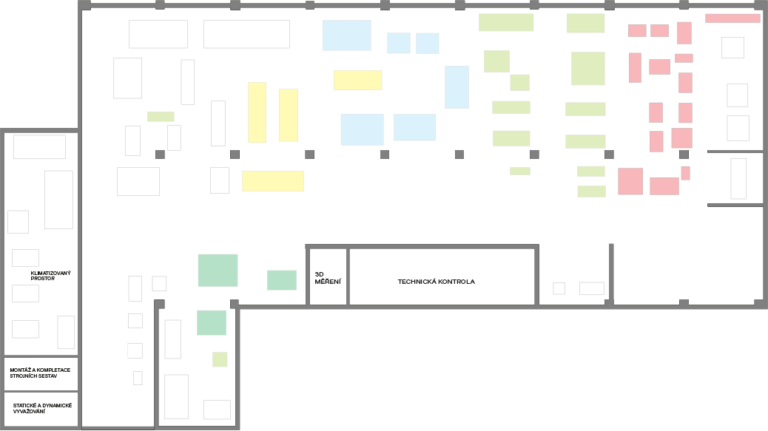

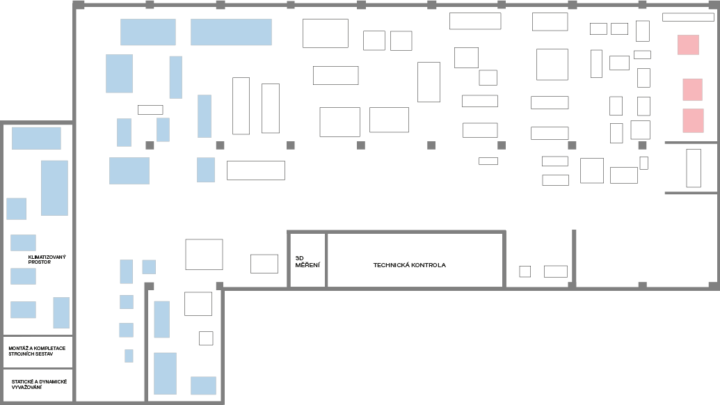

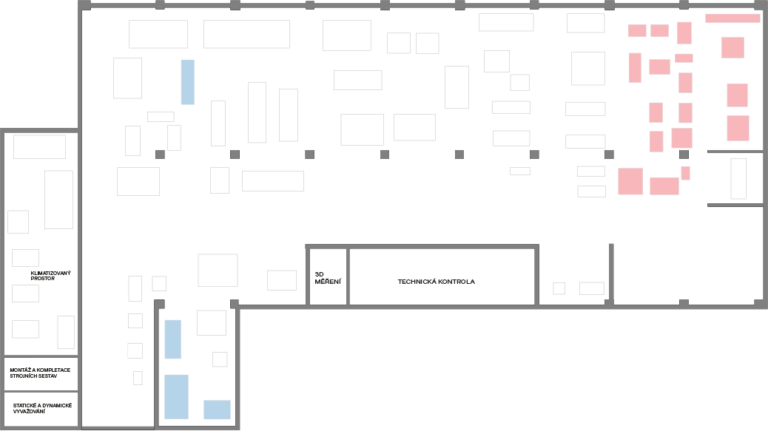

2 500m² of production area

PRECISE GRINDING

We specialize in producing comprehensive and precise machine components and parts by using cutting operation and precise grinding technologies. The parts are used for machine tools but also in food, chemical and aircraft industries.

2 500m² of production area

PRODUCTION PROFILE

Our production leans on grinders with many years of experience with producing precise and complicated machine parts.

We have 10 CNC machines including 5-axis turning centres and 35 conventional machines, from lathes, milling machines, boring machines to special machines for gearing.

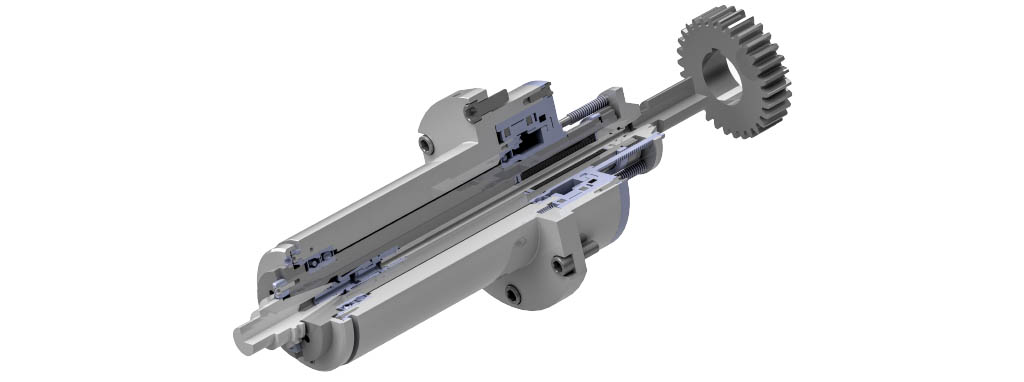

We produce and grind inner and outer gearing, straight and angled gearing, worms and worm gears, threads, inner and outer 6grooves.

We produce precise head stock parts for machine tool manufacturers worldwide and provide their diagnostics, repairs, balancing and running-in.

The parts are balanced up to the Q1 precision. We can measure the vibrations and imbalance directly on the machine with SCHENCK SmartBalancer.

5 technical inspection specialists, 3D measurements, regular customer audits and certification according to ISO 9001:2016.

In cooperation with other companies we provide annealing, heat treatment, cementation, hardening, nitriding, phosphatizing, galvanizing, nickeling and painting.

Our affiliated company AM-Metal s.r.o. provides metal plate processing via laser, punch preses, die-cutting, folding brake and welding.

Every year we pass customer quality audits and we have held the ISO 9001 certificate since 1998.

PerFe CZ a.s.

Blanenská 171/57

Kuřim 664 34

(Areal TOS Kuřim-hall no.9)

IČ: 46346627

DIČ: CZ46346627

Created ales@jedounek.eu

| Cookie | Délka | Popis |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

In cutting operations we use common but also special materials, e.g. stainless steel, duralumin, plastics or bronze. We have 10 CNC machines (4 lathes and 6 turning centres) and 35 conventional machines, from lathes, milling machines, boring machines to special machines for gearing.

Our production leans on grinders with many years of experience with producing precise and complicated machine parts. They can use 27 grinding machines – for round and hole grinding, flat grinding with longitudinal and circular feed, gearing, wormgears, threads and grooves. There are 7 grinding machines located in an air-conditioned area.

We produce and grind inner and outer gearing, straight and angled gearing, worms and worm gears, threads, inner and outer 6grooves. In the gearing area there are 9 milling machines, 4 gear shaping machines and 7 grinding machines for gearing, worms, threads and grooves.

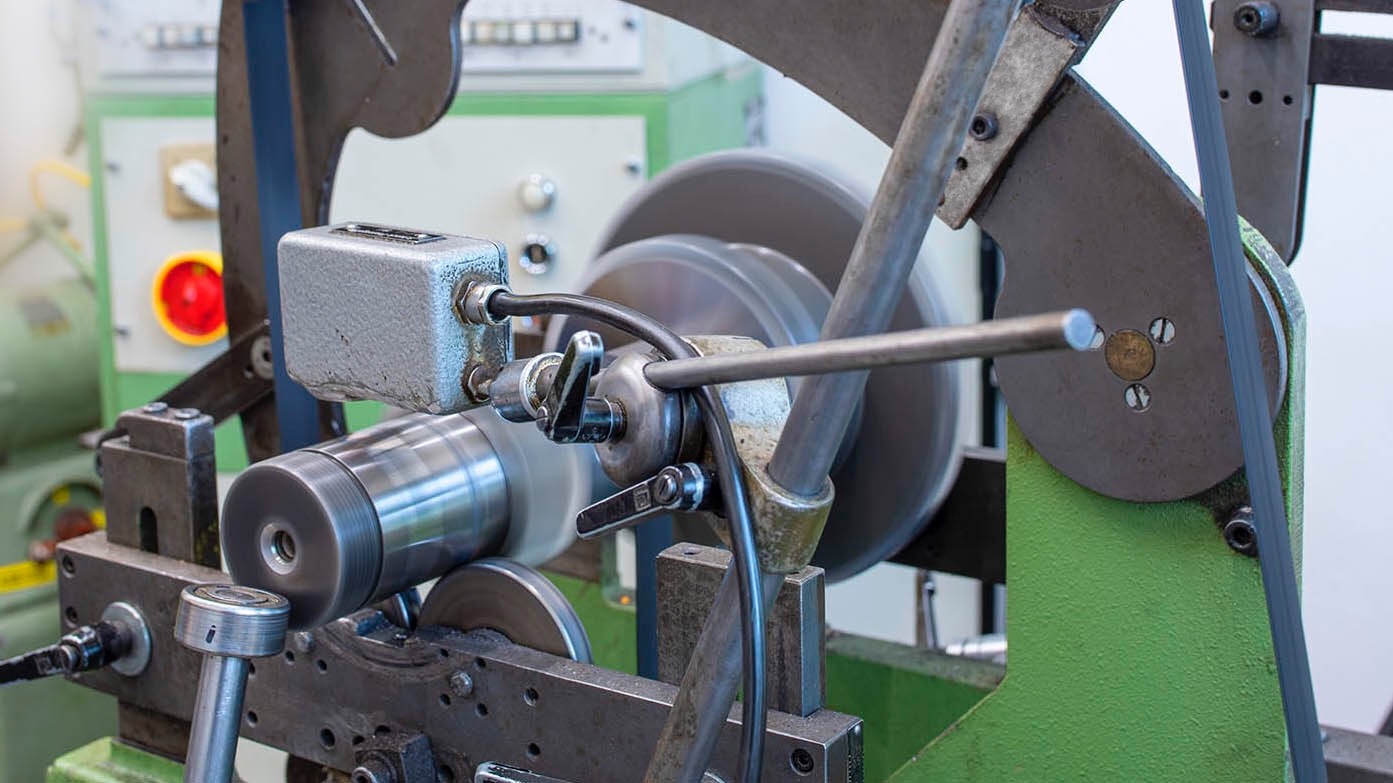

We repair spindles of CNC and conventional machine tools. We can diagnose imbalance and vibrations directly on the machine thanks to the SCHENCK SmartBalancer mobile measuring device.

In Kuřim there are 2 stationary SCHENCK dynamic balancing machines and a run-in machine with the temperature control.

We provide professional dismantling and final assembling directly at a customer site. Damaged part repairs, bearing replacements and trial runs are carried out in our balancing and fitting room in Kuřim.

Rotational parts are balanced up to the Q1 precision.

We produce precise head stock parts for machine tool manufacturers worldwide. We develop custom-made head stocks for special purpose machine tools.